Our Services

Installation

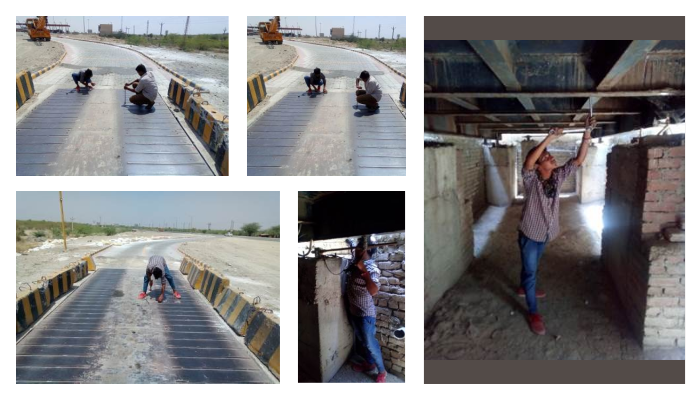

We provide installation and commissioning services for all types of dynamic and static weighbridges. We undertake –

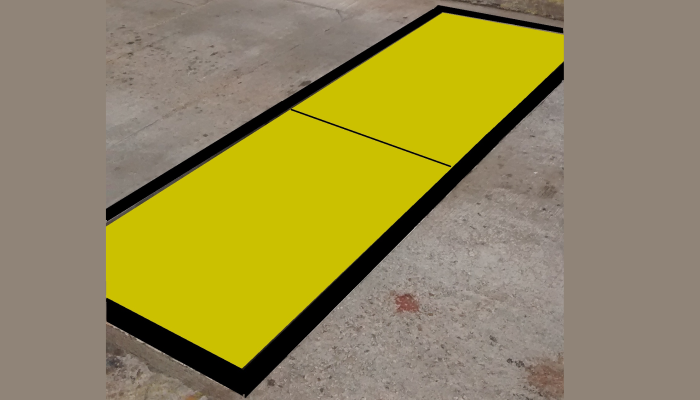

- Civil works for weighbridge installation (load cell and bending plate based technologies)

- Installation of weighing platform with load cells or bending plate scale

- System integration of the scale with weighing electronics, vehicle separator and toll management software

- Development of wrapper software (if required) in order to integrate weighing electronics output with Toll Management Software

- Calibration expertise to ensure best in class system accuracy and readiness for stamping by legal metrology department

- Handover of the system to customer after completing SAT.

Maintenance

Regular maintenance is a must to ensure best in class system accuracy and for achieving higher operational efficiency by reducing downtimes and extending equipment life. Our breadth of experience in this domain enables us to craft specific preventive maintenance schedules that target all the components of the system. We offer a range of customized annual maintenance contracts (AMCs) for our customers.

Non-comprehensive AMC

- Resolve break-down issues on priority

- 4 preventive maintenance visits per annum (Flexible)

- Option of on-site service engineer

- All Electronic and Mechanical components, cables are excluded and shall be replaced on a chargeable basis if needed

- This option does not cover the cost of stamping charges

- Cloud-based customised reporting and analytics.

Comprehensive AMC

- Resolve break-down issues on priority

- 4 to 12 preventive maintenance visits per annum

- Option of on-site service engineer

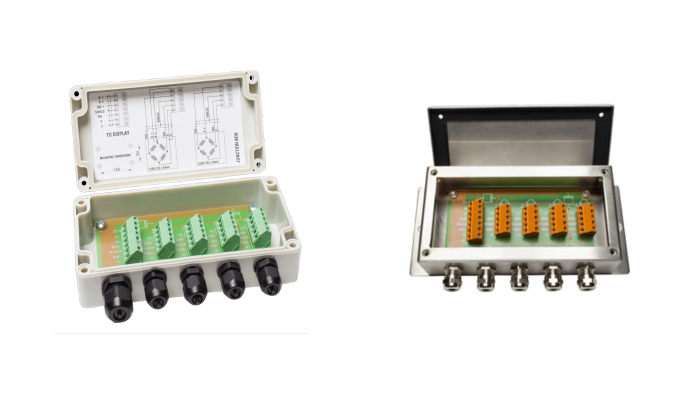

- The contract includes the cost for the repair of Indicator, Load cell, SPD Cum Junction Box and Cables/connectors where-ever possible

- The contract excludes the cost of major repair due to abuse, corrosion and rust because of chemical/adverse environmental conditions

- This option covers the cost of stamping charges

- Cloud-based customised reporting and analytics.

Calibration and Certification

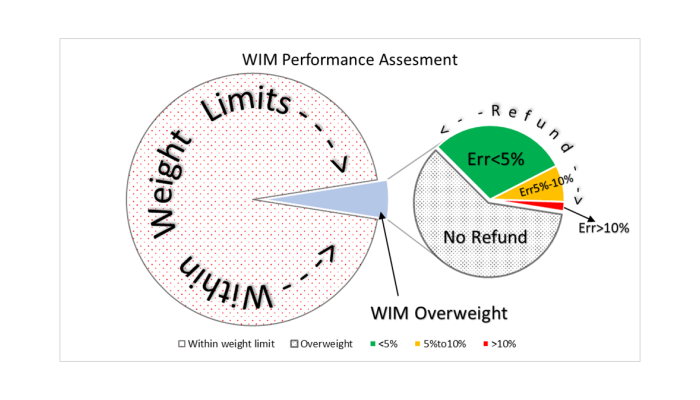

We offer calibration services for all types of Electronic Weigh bridges and Weigh in Motion Systems.

With sound understanding of calibration principles and methodology, we help our customers achieve best in class system accuracy and ensure system compliance to international (OIML) and domestic standards (Indian Legal Metrology guidelines).

Repair Service

Failure or non-performance will require that the WIM system is immediately restored to normal operation given that system uptime is imperative for profitability. WIM indicators and load cells are especially prone to failures due to electrical transients, lightning strikes, installation issues etc.

Our service technicians use the right tools and methodologies to identify and isolate root cause during the repair process. On request, we can provide failure reports and offer corrective actions/recommendations to avoid future issues. To date our team has repaired several models of third party weighing indicators, load cells and other electronic accessories used in the WIM systems and static weighbridges.

Spare Parts

We select spare parts to meet the quality objectives of customers. In the event the original part is not repairable and also not available, we shall offer a suitable replacement and help with system integration of the same with the toll management software.

List of Spares offered include –

- WIM Load Cell

- WIM Indicator

- Junction box for WIM

- SWB indicator

- SWB load cell

- Junction box for SWB

- Jumbo display

- Light Curtain

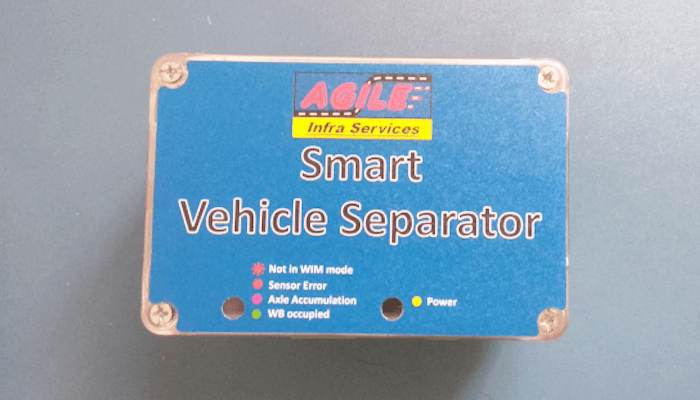

- Vehicle Separator Device

- Enclosure for Light Curtain

- Loop Detector and control box

- SMPS

- Cables and associated connectors for Load Cell and Light Curtain, Mechanical Consumables items for Weigh in Motion platform etc.

Upgrades and Refurbishment

Moving to the latest technology will lead to higher operational efficiency and revenue for customers. AIS team is trained to replace/upgrade legacy systems (for ex: load cell based WIM) with current state of the art technologies (For ex: Bending Plate).

Legacy WIM systems suffer from

- lower system performance due to component wear out

- unavailability of spare parts and trained service personnel

- issues arising from changing operational requirements etc.

Some of the key benefits with upgrading the system include –

- Refurbishing WIM system returns it to a safe, original manufactured condition

- Reduced down times and improved accuracy results in higher revenues and operational efficiency

- Lower cost of maintenance and higher reliability

- Availability of spare parts and experienced service professionals

- Compliance

to the latest standards and operational requirements - Indicator, peripherals or software upgrades enhance the functionality of your WIM system beyond its current capabilities.

Training & Consultancy

Dynamic weighing technology is a niche technical domain requiring an in depth understanding of the inter play between civil, mechanical and electrical engineering domains during installation & commissioning in order to achieve best in class system accuracy. We offer a wide range of training programs tailored to train customer maintenance and support teams. We ensure that our customers stay up-to-date with the latest developments in measurement technology, regulations and applications.

Our training programs can be customized and include the following –

- Standard or custom curriculum

- Expert instructors and trainers

- Comprehensive training material

- Competence testing and certification.

Custom Product Development Service

Our R&D team works closely with our sister concern – “Arete Automation Systems Pvt Ltd” and offers custom product development support to our customers. We also offer embedded and application software development for interfacing hardware to toll management software.

We have expertise in the development of the following products –

Hardware

- WIM Indicator

- Traffic counter system

- Vehicle separator system

- Vehicle positioning system

- Unmanned weigh bridges

- Automatic vehicle classification solution.

Software

- WIM wrapper software development and integration support for third party WIM indicators

- TMS custom software development with hardware integration, database management etc.